Published: |

Updated: |

Author:

Masayuki Kaneko

From centuries-old traditions to modern innovations, dress shoe construction includes a wide range of bottom-making techniques. In this guide, I explain ten major methods from a shoemaker’s perspective and highlight their characteristics along with representative brands.

Entering the World of Dress Shoe Construction | What to Know First

Shoe construction is more than a technical procedure—it’s a craft that carries the maker’s intent and creates footwear that accompanies your life. From years at the bench, I can say the construction method largely defines a shoe’s character.

This article covers 11 key methods used in contemporary shoemaking—from Goodyear welted to cemented—with historical context, technical features, and notable brands. Each method has its own aesthetics and functionality and serves different uses and tastes.

1. Goodyear Welted Construction

The mechanized revolution that defined classic dress shoes

Developed in late-19th-century America by Charles Goodyear Jr. (patented 1879), Goodyear welted construction mechanized what had previously been hand-welted work and enabled high-quality mass production.

Its core is a two-stage stitch system. The upper and welt are stitched to a rib attached to the insole (the inseam), then the welt is stitched to the outsole (the outsole stitch). Cork filling between insole and outsole adds cushioning and insulation.

Key advantages include excellent repairability—resoling can be done while keeping the welt—and inherent water resistance because stitches do not pass directly into the footbed. With proper care, a pair can serve you for decades.

Representative brands

United Kingdom

Church’s — a hallmark of British footwear since 1873

→ Official site

Edward Green — renowned at the very top end

→ Official site

Crockett & Jones — famously worn by James Bond

→ Official site

United States

Alden — among America’s most respected makers

→ Official site

Allen Edmonds — known for its 360° Goodyear welt

→ Official site

2. Hand-Sewn Welted (Hand Welted)

The pinnacle of handwork and fit

Hand-welted construction—also called the English welt—originated around the 15th–16th centuries and remained the standard for fine footwear before Goodyear machines. Today it thrives in bespoke and limited high-end production.

Instead of attaching a separate rib to the insole, a holdfast (feather) is carved directly from the insole leather. The maker hand-stitches the insole, upper, lining, and welt with a curved awl and boar bristle or curved needle, then stitches the welt to the outsole.

Hand-welted shoes flex well from day one and feel soft underfoot. Without a bulky cork layer, the insole itself molds to the foot, delivering a unique, increasingly personalized fit.

Representative brands

Bespoke / High-end

John Lobb — benchmark craftsmanship in its bespoke department

→ Official site

Edward Green — offered within its bespoke program

→ Official site

Japan

Union Imperial — Dress PREMIUM line

→ Official site

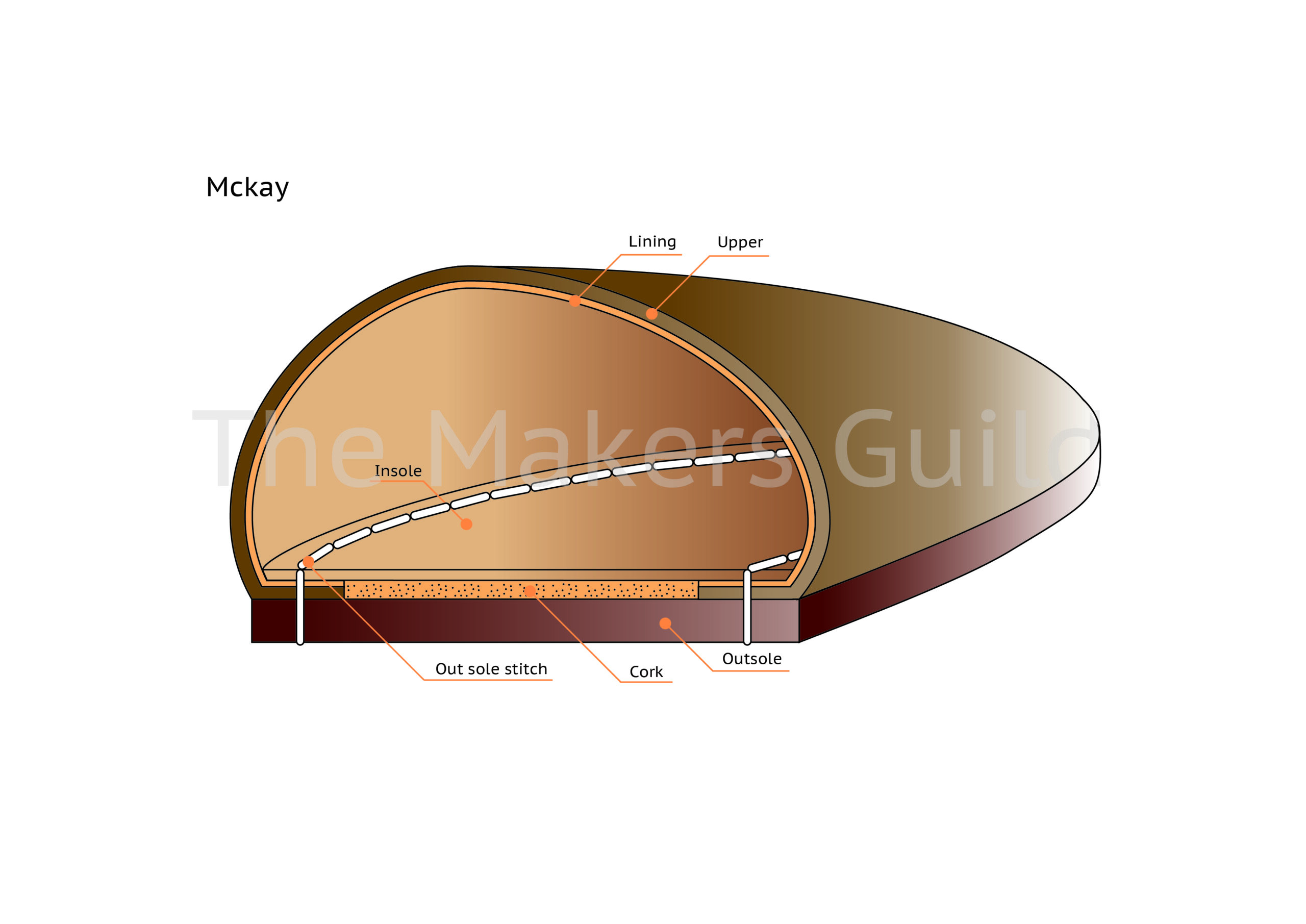

3. McKay/Blake Construction

Italian elegance with a flexible, lightweight build

Patented in 1856 by Lyman Reed Blake and industrialized by Gordon McKay, this was the first machine-sewn bottoming method. It is now widely used across Europe, especially in Italy’s Marche region.

The insole, upper, and outsole are sewn together in one pass from inside the shoe (Blake stitch). Without a separate welt or mid-fill, the shoe can be thinner and lighter with a clean, elegant profile.

Its great appeal is flexibility and lightness. The thin sole bends easily, feeling supple right from the start—often described as “as light as wearing socks.”

Representative brands

Italy / Spain

Salvatore Ferragamo — frequently used on moccasin-style models

→ Official site

Tod’s — iconic driving shoes

→ Official site

Magnanni — Spanish maker with refined Blake work

→ Official site

Japan / Spain

Scotch Grain — used in selected models

→ Official site

Berwick 1707 — strong value for money

→ Official site

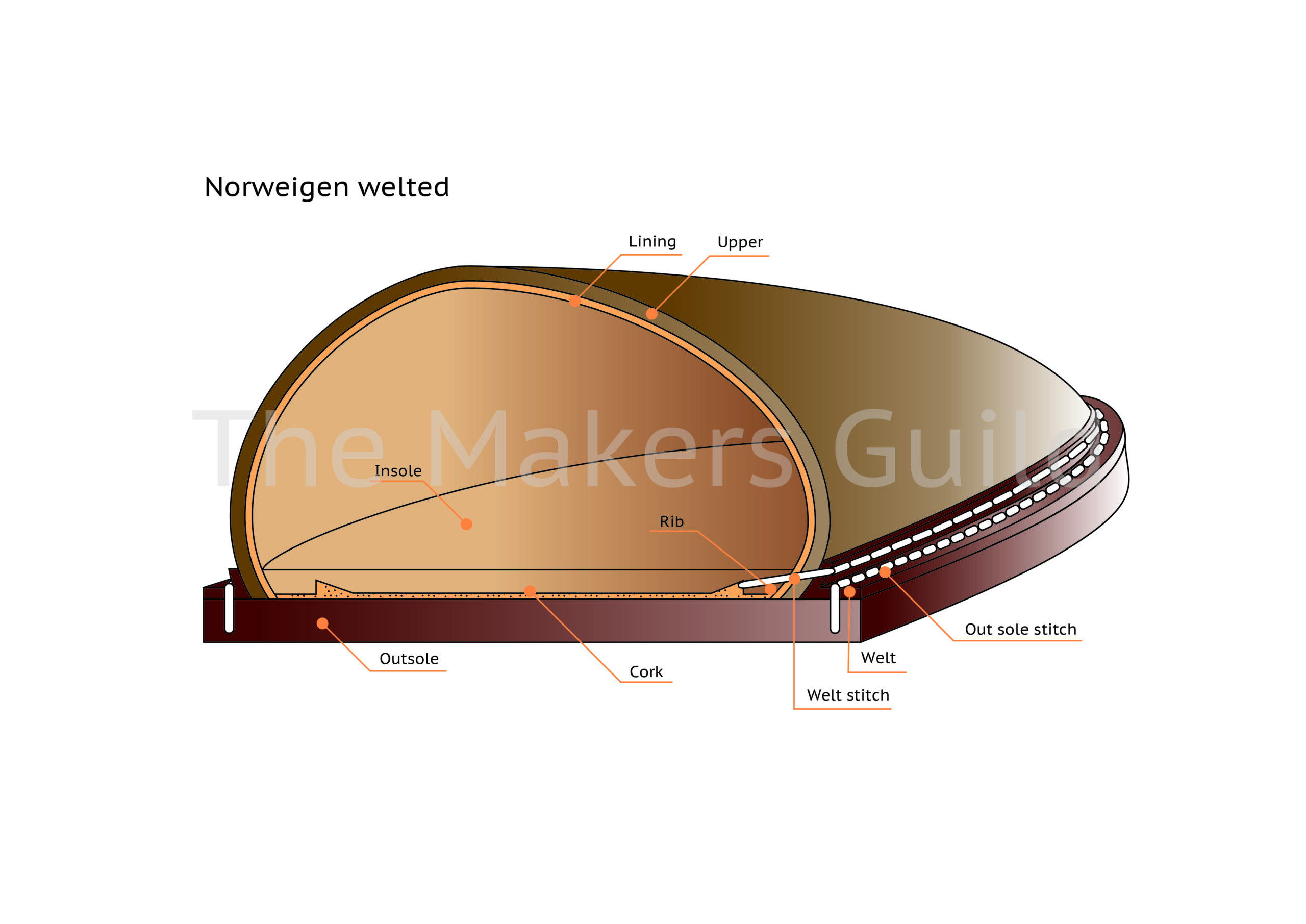

4. Norwegian Welt Construction

Built for harsh climates with outstanding water resistance

Originating in Scandinavia for cold, wet conditions, Norwegian welting became common in mountaineering and ski boots from the late 19th to early 20th centuries and was used for Northern European military boots during WWII.

Here the upper edge is not turned inward but spread outward and stitched to the insole. An L-shaped welt links upper and insole, and the outsole is stitched again—creating two visible rows of stitching along the edge.

Because the stitches do not pass directly into the interior, this method excels at keeping water out. A midsole-plus-outsole stack also blocks moisture and cold, making it ideal for snowy or rainy environments.

Representative brands

France

Paraboot — the emblematic maker; “Michael” is iconic

→ Official site

Hungary

Vass — heavy-duty boots also known as Goiser welt

→ Official site

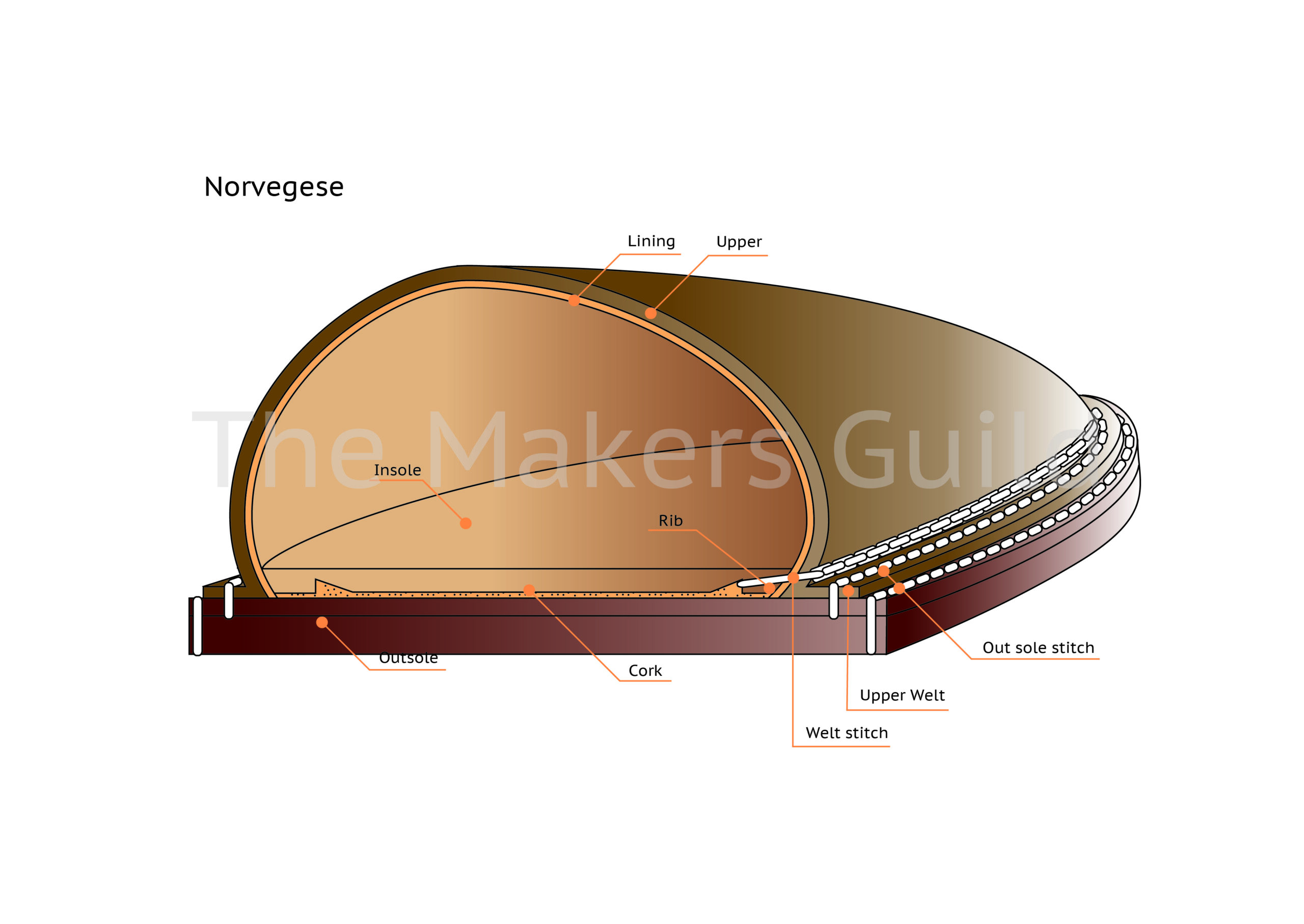

5. Norvegese Construction

Exuberant Italian stitchwork as wearable art

Refined in the early 1990s by Italian shoemaker Stefano Branchini, Norvegese evolved from the Norwegian welt but embraces Italian aesthetics—highly decorative and artisanal. Only a handful of top Italian makers execute it today.

Typically the sole is secured with three rounds of stitching. The upper itself acts as a “welt” for twin outsoles, and the work is entirely hand-sewn. Heavy skin stitches and precise chain stitches around the edge give an unmistakable sculptural look.

The result is visually striking and substantial—often appreciated as much for its artistry as for wear. It’s a statement method with commanding presence.

Representative brands

Italy

Santoni — used in limited editions

→ Official site

Stefano Branchini — the method’s modern champion

→ Official site

Stefano Bemer — available via bespoke

→ Official site

Practical Guidance for Choosing a Construction

Match your method to use case and comfort

Choosing a construction is ultimately about aligning with your lifestyle and values. For day-to-day business use, the durability and repairability of Goodyear welted shoes are excellent. If you prefer a lighter, more flexible feel, Blake (McKay) may suit you better.

Considering Japan’s climate, waterproof-leaning Norwegian welt shoes shine during rainy seasons. Foot shape matters too: flatter feet often appreciate the supportive insole and cork bed of Goodyear welts, while high insteps may enjoy the flex of Blake.

Price tiers also correlate with methods. Cemented is a good entry point at accessible prices, while hand-welted shoes are long-term investments. The key is balancing budget with the quality and longevity you expect.

Common Misconceptions to Avoid

What’s often misunderstood—and the reality

One widespread myth is that “the more expensive the method, the better.” While hand-welted is indeed top tier, for frequent office wear Goodyear welted or Blake can be more practical depending on your needs.

Another belief is that “Goodyear welted is always heavy.” Modern materials and builds can be quite light. Conversely, not all Blake shoes are ultralight—the leather and sole thickness influence weight significantly.

Repairs also cause confusion. You may hear “Blake can’t be resoled.” That’s incorrect—while more specialized than Goodyear repairs, competent cobblers can resole Blake shoes. When buying, ask about future repair options.

A Shoemaker’s Perspective: Choosing What Truly Fits Your Life

The real value of construction

The goal isn’t to rank methods but to select the one that resonates with your philosophy and use. Each construction embodies a distinct approach—choose the one that complements your rhythm of life.

The steady, maintainable nature of Goodyear welted suits long-term thinkers. The lively flex of Blake appeals to those who value lightness and change. Hand-welted captures a reverence for tradition and uncompromising quality.

As a Japanese maker, I hope these methods help you appreciate the diversity of global shoe culture. Understanding the craft and passion invested in a pair leads to deeper satisfaction and smarter choices.

Quick guide to choosing

• Practical daily wear: Goodyear welted

• Light and flexible: Blake (McKay)

• Weather resistance: Norwegian welt

• Top craftsmanship: Hand-welted

• Artistic statement: Norvegese

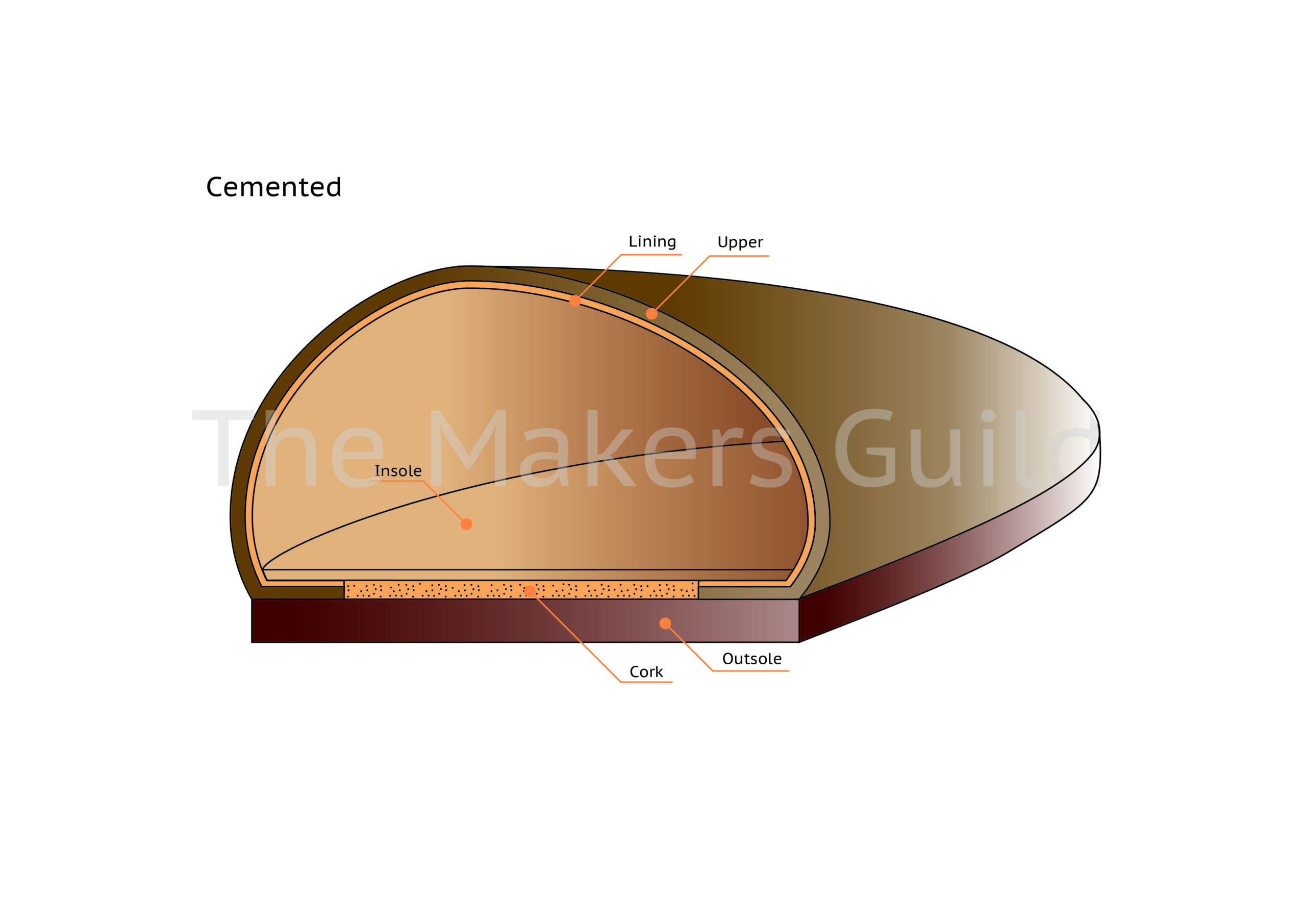

6. Cemented Construction

Modern efficiency for scalable production

Cemented construction bonds outsole and upper with adhesives. Popular since the mid-20th century, it’s among the most widely used methods today. Without stitching, it enables efficient mass production at accessible prices.

The big advantage is simplified workflow with strong, flexible bonds using modern adhesives. Designers also enjoy broad freedom in sole thicknesses and materials.

Repair options are limited—resole work is often not economical—yet quality cemented shoes can be durable for everyday wear when well made.

Representative brands

Japan

REGAL — used on entry models

→ Official site

International

Cole Haan — contemporary designs with comfort features

→ Official site

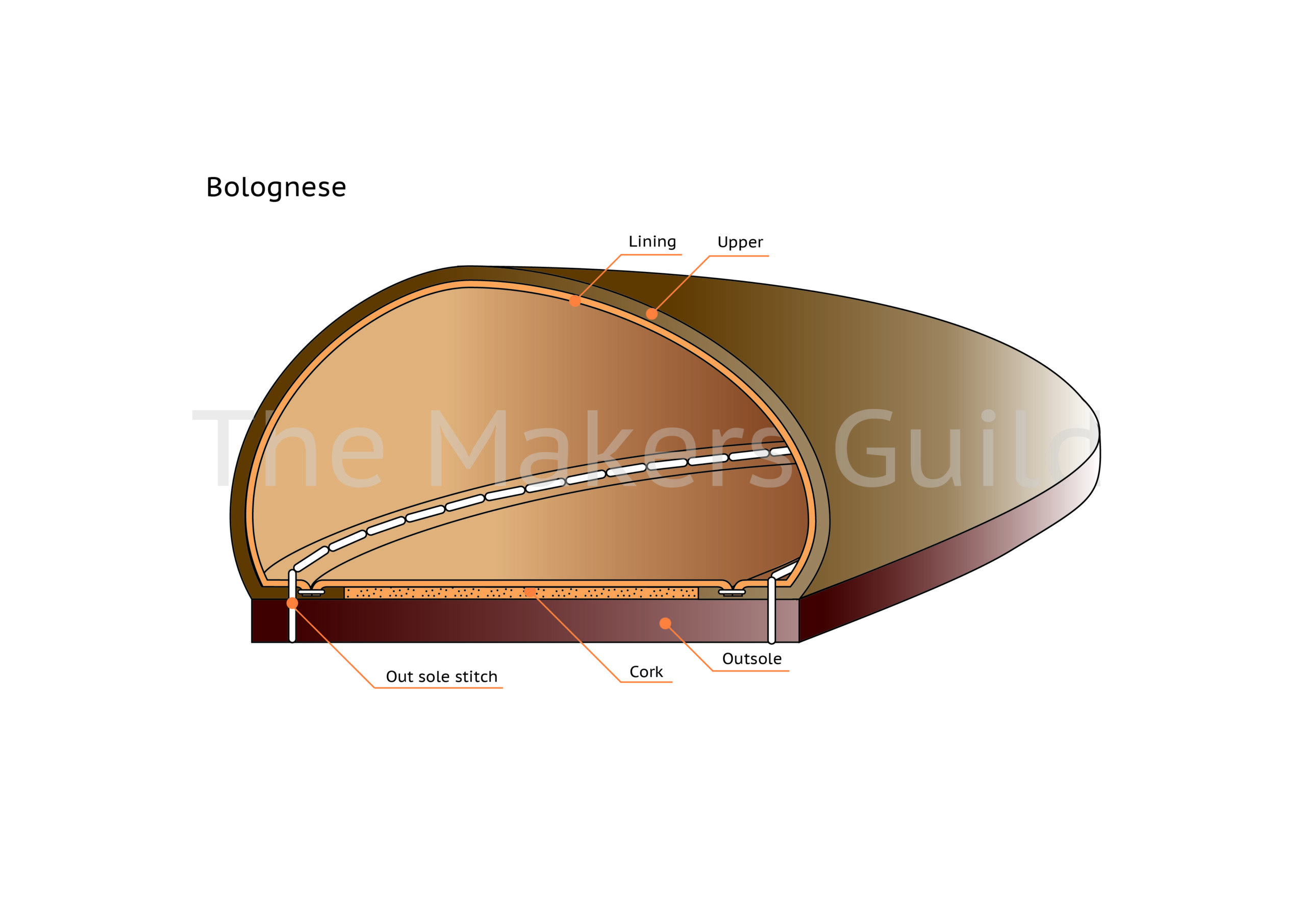

7. Bologna (Bolognese) Construction

Sock-like comfort born in Bologna

Derived from Blake, Bologna construction sews the upper and lining into a bag before bottoming. With no traditional insole board, the foot is cradled directly by leather, delivering exceptional flexibility and comfort.

The result is very light and pliable—often used for loafers and moccasins across casual to business-casual settings.

It requires advanced skill for a clean result, so relatively few makers offer it, many of them high-end Italian workshops.

Representative brands

Italy

Stefano Branchini — noted for Bologna craftsmanship

→ Official site

Enzo Bonafé — traditional Bolognese technique

→ Official site

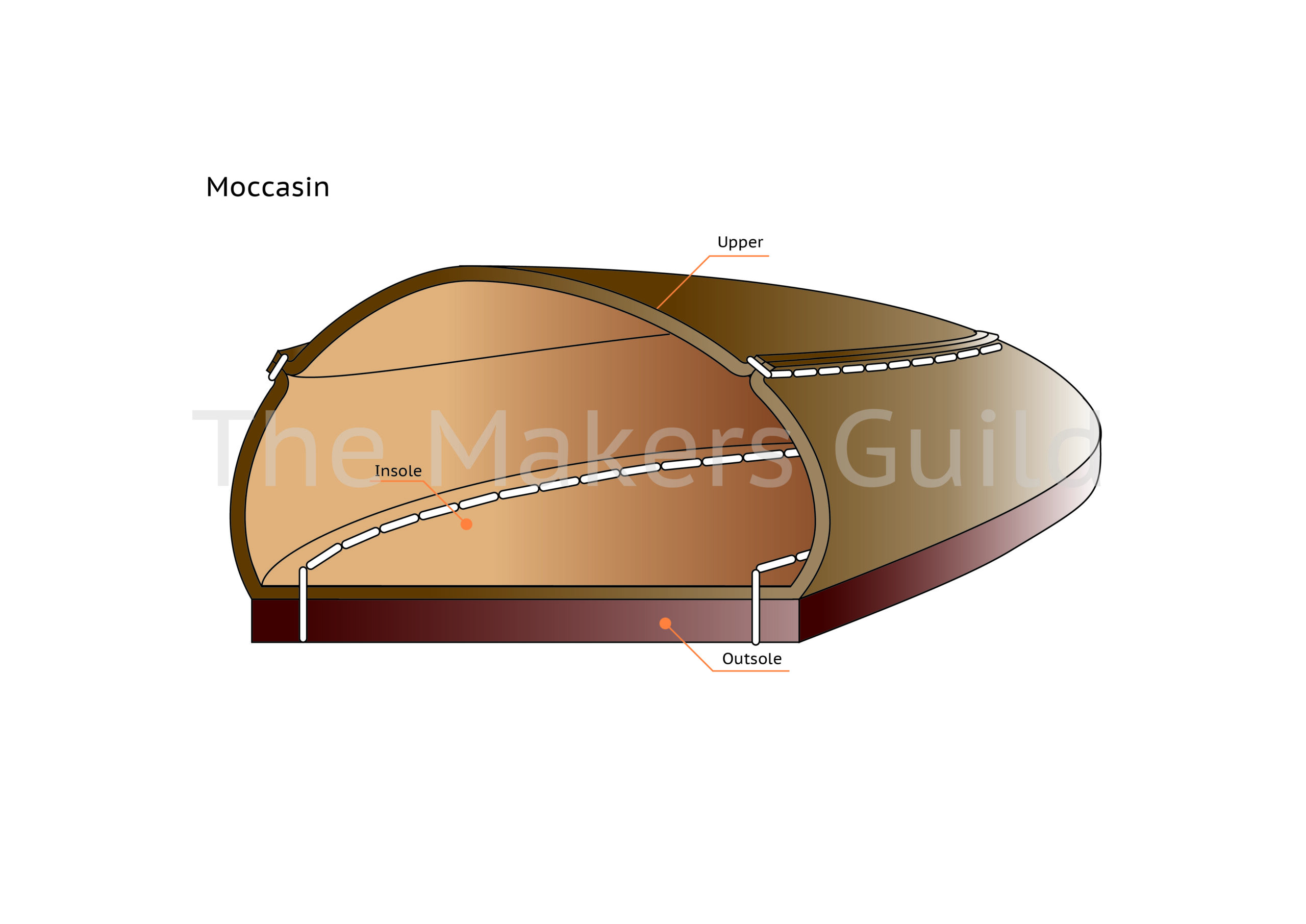

8. Moccasin Construction

Native American wisdom adapted for modern wear

Among the oldest techniques, moccasin construction wraps the foot in a single piece of leather with a separate vamp stitched on top—delivering an exceptionally natural feel. Today it appears in loafers, deck shoes, and driving shoes.

Because the foot rests directly on leather rather than an insole board, the shoe molds closely to your foot over time. Fewer seams keep weight low and comfort high over long hours.

Many modern moccasins add rubber outsoles or combine with Blake stitching for durability—marrying classic comfort with contemporary performance.

Representative brands

United States

Minnetonka — a classic name in moccasins

→ Official site

Sebago — renowned for deck shoes

→ Official site

Italy

Tod’s — the benchmark for driving shoes

→ Official site

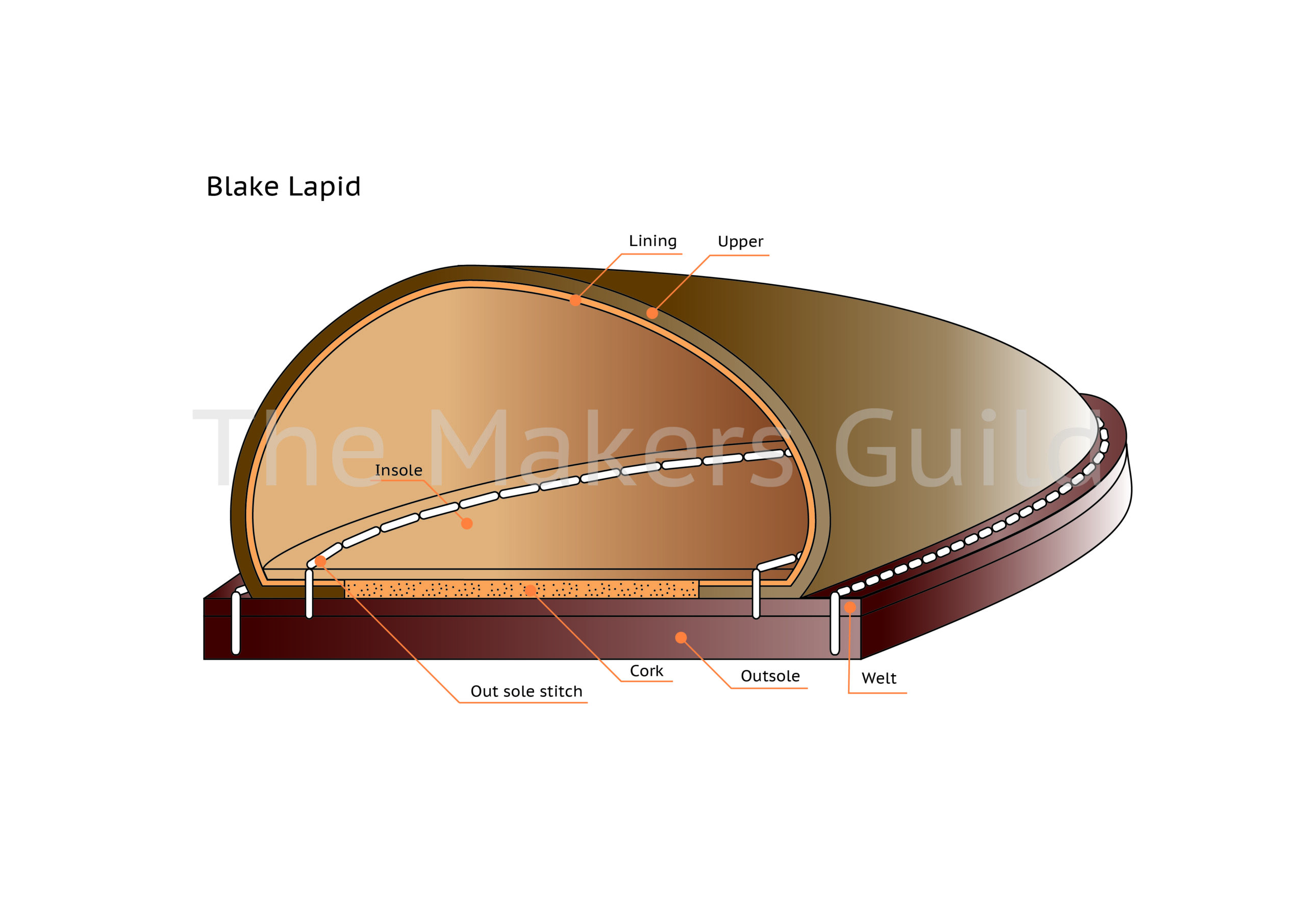

9. Blake Rapid Construction

A hybrid that blends flexibility and durability

Developed in Italy, Blake Rapid combines advantages of Blake and welt-like outsole stitching. The insole, upper, and midsole are sewn with a Blake stitch; then the outsole is attached and stitched to the midsole—yielding a distinctive ride.

It retains Blake’s flexibility while enabling more outsole variety and easier resoles. It’s popular for smart-casual designs bridging formal and casual wardrobes.

Costs are higher than pure Blake yet generally below hand-welted; resoling is typically feasible following Blake practices.

Representative brands

Italy

Santoni — masters of multiple methods

→ Official site

Fratelli Rossetti — known for innovation

→ Official site

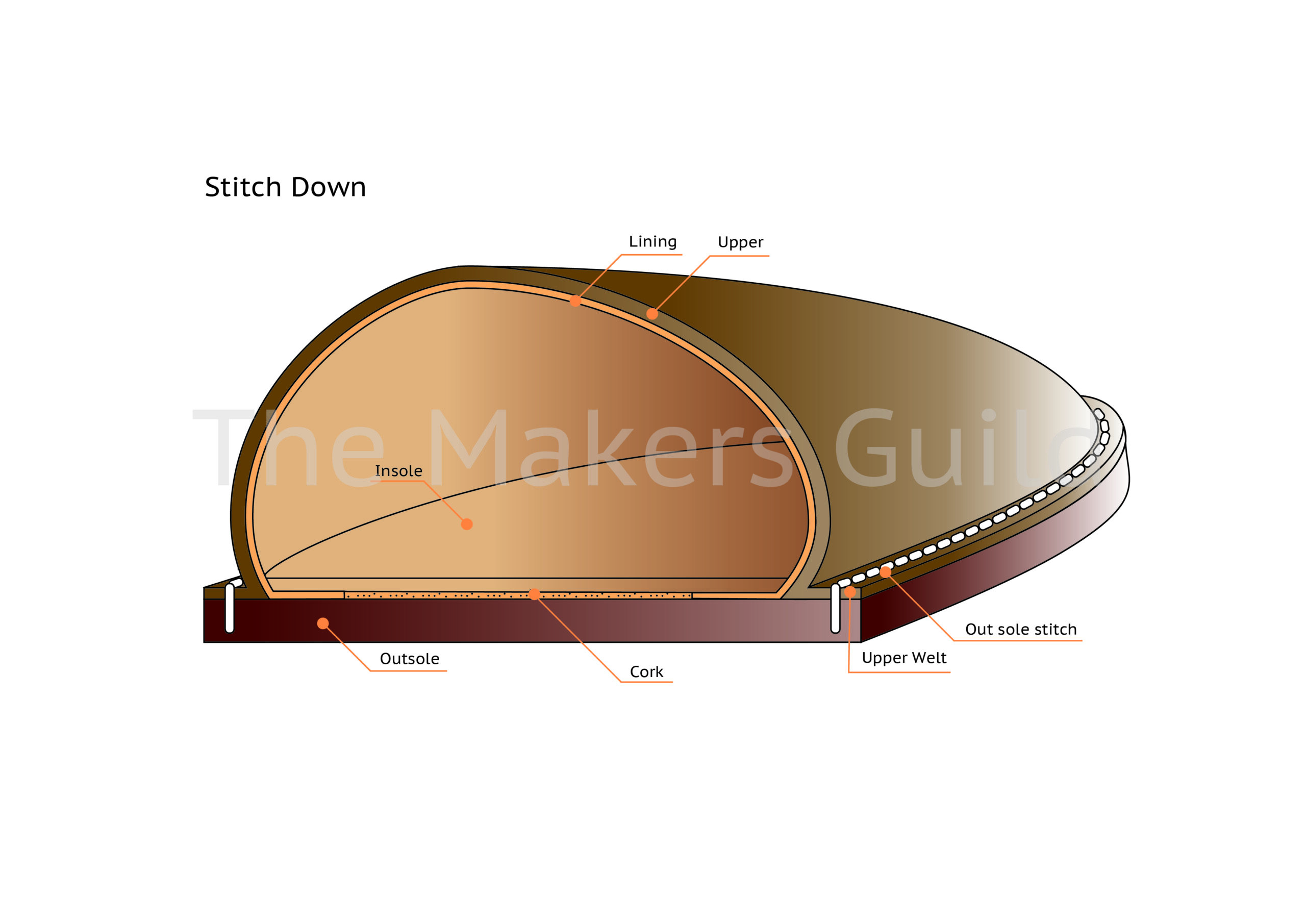

10. Stitchdown Construction

Utilitarian roots from the American frontier

Evolving in 19th-century America, stitchdown folds the upper outward onto the midsole/outsole and stitches through—creating robust, water-resistant boots favored for work and the outdoors.

Because the upper and sole are joined directly, the structure is extremely strong and serviceable. Visible exterior seams also make repairs relatively straightforward.

The look is rugged by design—perfect for work and outdoor boots—and modern fashion takes have brought stitchdown into casual wear as well.

Representative brands

United States

L.L.Bean — famed for the Bean Boot

→ Official site

Russell Moccasin — hunting boot specialists

→ Official site

Danner — a leader in outdoor boots

→ Official site

Sponsorship Information

“The Makers Guild” is an international community site that shares craft and shoe culture. We are currently welcoming sponsorships from partners who support our mission.